Table of Contents

Toggle

Section 1: Unveiling the Powerhouse

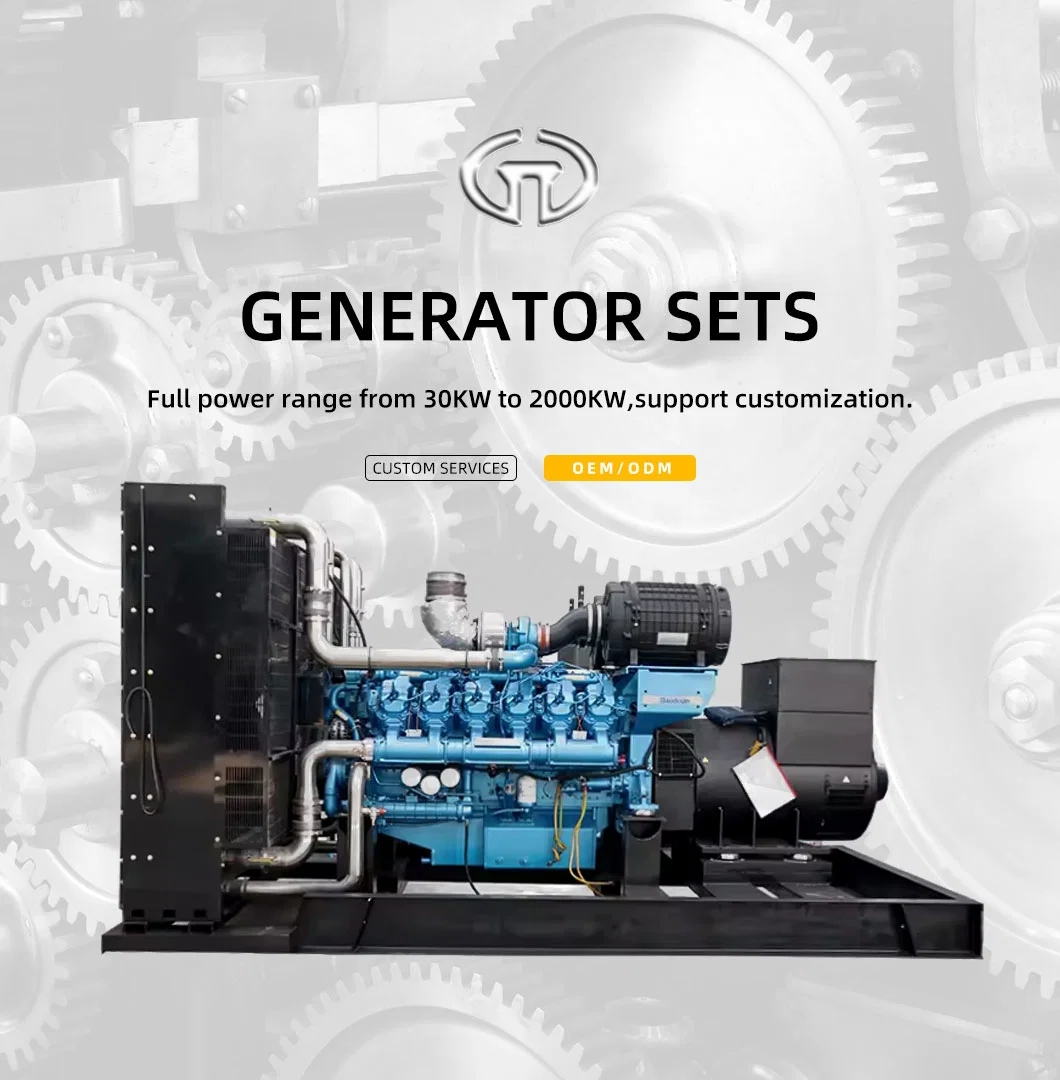

In the realm of power generation, the 150kW diesel generator stands as a robust and versatile solution, catering to diverse industrial, commercial, and agricultural applications. This formidable machine harnesses the might of diesel fuel, delivering a steady stream of electricity to keep critical operations running seamlessly, even in the face of grid outages or remote locations.

Engineered to withstand the harshest environments, these generators boast rugged construction and cutting-edge technologies, ensuring unparalleled performance and reliability. From powering factories and warehouses to illuminating construction sites and energizing remote farms, the 150kW diesel generator emerges as an indispensable ally for businesses and communities alike.

Unleashing Uninterrupted Power

In an era where power disruptions can cripple operations and lead to significant losses, the 150kW diesel generator stands as a bulwark against such adversities. Its robust design and ample power output make it an ideal choice for ensuring continuous and uninterrupted power supply, safeguarding critical processes, and minimizing costly downtime.

Versatility Across Industries

The versatility of the 150kW diesel generator is one of its most remarkable attributes. These powerhouses find applications in a wide array of sectors, including:

- Industrial facilities: Powering manufacturing processes, machinery, and equipment.

- Construction sites: Providing reliable energy for tools, lighting, and site operations.

- Healthcare facilities: Ensuring uninterrupted power for life-saving equipment and systems.

- Telecommunication networks: Maintaining consistent power supply for data centers and communication infrastructure.

- Agricultural operations: Energizing farms, irrigation systems, and agricultural machinery.

Robust and Efficient Engineering

Behind the impressive performance of the 150kW diesel generator lies a symphony of robust engineering and advanced technologies. These generators typically feature powerful diesel engines from renowned manufacturers, such as Cummins, Perkins, or John Deere, renowned for their durability and fuel efficiency.

The heart of the generator is a robust alternator, designed to convert the mechanical energy from the engine into electrical power with exceptional precision and efficiency. Advanced electronic controls and monitoring systems further enhance the generator’s performance, ensuring precise voltage and frequency regulation, and providing real-time data and diagnostics.

Section 2: Exploring the Diesel Advantage

Diesel generators have long been favored for their reliability, fuel efficiency, and cost-effectiveness. The 150kW diesel generator, in particular, offers a compelling combination of advantages that make it a preferred choice for many applications.

Fuel Efficiency and Cost Savings

One of the primary advantages of diesel generators is their exceptional fuel efficiency. Diesel engines are renowned for their ability to extract more energy from each drop of fuel, resulting in lower operating costs and reduced environmental impact. This fuel efficiency translates into substantial cost savings over the generator’s lifetime, making it an economically viable investment for businesses and organizations.

Robust and Durable Construction

Diesel generators are built to withstand the rigors of demanding environments and continuous operation. Their robust construction, featuring heavy-duty components and sturdy enclosures, ensures longevity and resilience. These generators are designed to operate reliably in extreme temperatures, dusty conditions, and challenging terrains, making them well-suited for applications in remote locations or harsh industrial settings.

Low Maintenance Requirements

Compared to other generator types, diesel generators generally require less frequent maintenance, reducing downtime and associated costs. Their simple design and robust components contribute to lower maintenance requirements, minimizing the need for complex repairs or replacements. Regular oil changes, filter replacements, and routine inspections are typically sufficient to keep these generators operating at peak performance for extended periods.

Emissions Compliance

Modern diesel generators are engineered to meet stringent emissions regulations, ensuring compliance with environmental standards while maintaining high levels of performance. Manufacturers employ advanced technologies, such as selective catalytic reduction (SCR) systems and diesel particulate filters (DPF), to reduce harmful emissions and minimize the environmental impact of these generators.

Section 3: Powering Critical Operations

In today’s fast-paced world, where uninterrupted power supply is crucial for maintaining business continuity and ensuring public safety, the 150kW diesel generator plays a pivotal role in powering critical operations across various sectors.

Industrial Applications

Industrial facilities, such as manufacturing plants, processing units, and warehouses, rely heavily on a consistent and reliable power supply to keep their operations running smoothly. The 150kW diesel generator serves as a dependable backup power source, ensuring that production lines, machinery, and essential systems continue to function even during grid outages or emergencies.

Healthcare Facilities

In the healthcare sector, where lives are at stake, the importance of uninterrupted power cannot be overstated. Hospitals, clinics, and medical research facilities depend on 150kW diesel generators to provide emergency power for life-support systems, diagnostic equipment, and critical infrastructure. These generators ensure that patient care and vital research activities can continue without interruption, even in the event of a power outage.

Telecommunication Networks

The modern world’s reliance on communication and data networks has made the availability of uninterrupted power a critical necessity. Data centers, telecommunication towers, and network infrastructure rely on 150kW diesel generators to maintain continuous operation, preventing data loss, service disruptions, and potential financial losses for businesses and individuals alike.

Construction and Mining Sites

Construction and mining sites often operate in remote locations, where access to grid power can be limited or unreliable. The 150kW diesel generator becomes an essential power source for these sites, providing the necessary energy to run heavy machinery, lighting systems, and other essential equipment. These generators ensure that projects can progress without interruption, minimizing delays and maximizing productivity.

Emergency Response and Disaster Relief

During natural disasters or emergencies, reliable power is crucial for coordinating rescue efforts, powering shelters, and supporting critical infrastructure. The 150kW diesel generator plays a vital role in these situations, providing a dependable source of electricity for emergency response teams, temporary medical facilities, and relief operations, helping to save lives and mitigate the impact of such events.

Section 4: Agricultural Empowerment

The agricultural sector has long recognized the importance of reliable power sources, and the 150kW diesel generator has emerged as a trusted ally for farmers and agricultural businesses.

Powering Remote Farms and Facilities

Many agricultural operations are located in remote areas, where access to the grid can be limited or unreliable. The 150kW diesel generator ensures that these farms and facilities have a consistent and dependable power supply, enabling them to operate essential equipment, irrigation systems, and other critical systems without interruption.

Safeguarding Crops and Livestock

Power outages can have devastating consequences for agricultural operations, putting crops and livestock at risk. The 150kW diesel generator serves as a lifeline, providing the necessary power to maintain optimal conditions for crop growth, livestock health, and overall farm productivity. By ensuring uninterrupted power, these generators help protect valuable investments and minimize potential losses.

Enabling Efficient Operations

Modern agricultural practices rely heavily on advanced technologies and equipment, such as automated systems, precision farming tools, and processing machinery. The 150kW diesel generator powers these essential components, enabling efficient and streamlined operations, from planting and harvesting to processing and storage.

Supporting Agri-Tourism and Hospitality

In recent years, many agricultural businesses have diversified their offerings by incorporating agri-tourism and hospitality services. These ventures often require reliable power sources to support guest accommodations, event spaces, and recreational facilities. The 150kW diesel generator provides the necessary energy to ensure a seamless and enjoyable experience for visitors, while also powering the farm’s core operations.

Section 5: Robust and Resilient Design

The 150kW diesel generator is engineered to withstand the most demanding conditions, ensuring reliable performance and longevity in even the harshest environments.

Rugged Construction

These generators feature robust construction, with heavy-duty components and sturdy enclosures designed to withstand extreme temperatures, dust, and other challenging environmental factors. The use of high-quality materials, such as corrosion-resistant metals and durable plastics, ensures that the generator can withstand the rigors of outdoor operation and harsh industrial settings.

Vibration Isolation and Noise Reduction

To minimize vibration and noise levels, the 150kW diesel generator incorporates advanced vibration isolation systems and sound-attenuating enclosures. These features not only enhance the generator’s operational smoothness but also contribute to a more comfortable working environment for operators and nearby personnel.

Cooling Systems and Environmental Protection

Efficient cooling systems are essential for ensuring the generator’s optimal performance and longevity. Many 150kW diesel generators incorporate advanced cooling technologies, such as liquid cooling systems or specialized air-cooling mechanisms, to maintain ideal operating temperatures even under heavy loads or extreme ambient conditions.

Additionally, manufacturers prioritize environmental protection by incorporating features like spill containment basins and emissions control systems, minimizing the generator’s impact on the surrounding environment.

User-Friendly Controls and Monitoring

Modern 150kW diesel generators are equipped with user-friendly control panels and monitoring systems, allowing for easy operation and real-time performance tracking. These systems often include features like automatic start/stop controls, fault diagnostics, and remote monitoring capabilities, enabling efficient management and maintenance of the generator.

Section 6: Fuel Efficiency and Cost-Effectiveness

In today’s cost-conscious business environment, fuel efficiency and cost-effectiveness are critical factors when selecting a power generation solution. The 150kW diesel generator excels in both areas, offering significant advantages over other generator types.

Maximizing Fuel Efficiency

Diesel engines are renowned for their exceptional fuel efficiency, and the engines powering 150kW generators are no exception. These engines are designed to extract maximum energy from every drop of diesel fuel, resulting in lower fuel consumption and reduced operating costs.

Manufacturers employ advanced technologies, such as common rail fuel injection systems, turbochargers, and electronic engine controls, to optimize fuel efficiency further. These innovations ensure that the generator operates at peak performance while minimizing fuel consumption and associated expenses.

Reduced Operating Costs

In addition to fuel savings, the 150kW diesel generator offers lower operating costs in several other areas. These generators typically require less frequent maintenance compared to other generator types, reducing downtime and associated labor costs.

Furthermore, the robust construction and high-quality components used in these generators contribute to their longevity, minimizing the need for frequent repairs or replacements. This translates into significant cost savings over the generator’s lifetime, making it a cost-effective investment for businesses and organizations.

Fuel Flexibility and Availability

While diesel generators primarily run on diesel fuel, many models offer the flexibility to operate on alternative fuels, such as biodiesel or fuel blends. This fuel flexibility can provide additional cost savings and environmental benefits, depending on the availability and pricing of these alternative fuel sources in a particular region.

Moreover, the widespread availability of diesel fuel worldwide ensures a reliable and consistent fuel supply, minimizing the risk of operational disruptions due to fuel shortages.

Lifecycle Cost Analysis

When evaluating the cost-effectiveness of a 150kW diesel generator, it is essential to consider the total lifecycle cost, which encompasses not only the initial purchase price but also factors like fuel consumption, maintenance expenses, and operational costs over the generator’s lifespan.

By conducting a comprehensive lifecycle cost analysis, businesses and organizations can accurately assess the long-term financial implications of investing in a 150kW diesel generator and make informed decisions that align with their budgetary constraints and operational requirements.

Section 7: Emission Compliance and Environmental Responsibility

As environmental concerns continue to gain prominence, the power generation industry has embraced stringent emissions regulations and sustainable practices. The 150kW diesel generator market has responded by incorporating advanced technologies and adhering to stringent emissions standards, ensuring compliance while maintaining high levels of performance.

Meeting Emissions Regulations

Leading manufacturers of 150kW diesel generators prioritize compliance with regional and global emissions regulations, such as the Environmental Protection Agency (EPA) standards in the United States and the European Union’s Stage V emissions standards.

To achieve compliance, these generators employ cutting-edge technologies like selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and exhaust gas recirculation (EGR) systems. These technologies work in tandem to reduce harmful emissions, including nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO), while maintaining the generator’s power output and efficiency.

Embracing Sustainable Practices

Beyond emissions compliance, manufacturers are increasingly incorporating sustainable practices into the design and production of 150kW diesel generators. These efforts include the use of recycled materials, energy-efficient manufacturing processes, and responsible waste management strategies.

Additionally, many generators now feature advanced monitoring and control systems that optimize fuel consumption and minimize emissions, further contributing to environmental sustainability.

Lifecycle Environmental Impact

When evaluating the environmental impact of a 150kW diesel generator, it is crucial to consider its entire lifecycle, from manufacturing and operation to decommissioning and disposal. Manufacturers are increasingly adopting a cradle-to-grave approach, ensuring that the generator’s environmental footprint is minimized at every stage of its lifecycle.

This holistic approach includes the responsible sourcing of raw materials, energy-efficient production processes, and the implementation of end-of-life recycling and disposal programs, minimizing the generator’s overall environmental impact.

Renewable Energy Integration

As the adoption of renewable energy sources continues to grow, the power generation industry is exploring ways to integrate these clean energy sources with traditional generators. In this context, the 150kW diesel generator can play a complementary role, providing backup power or load-balancing capabilities in hybrid renewable energy systems.

By combining the reliability and versatility of diesel generators with renewable energy sources like solar or wind power, businesses and communities can achieve a more sustainable and resilient power supply while reducing their overall carbon footprint.

Section 8: Customization and Versatility

One of the key strengths of the 150kW diesel generator lies in its ability to be customized and tailored to meet specific application requirements. This versatility ensures that businesses and organizations can obtain a power generation solution that aligns perfectly with their unique needs, maximizing efficiency and optimizing performance.

Enclosure Options

Manufacturers offer a wide range of enclosure options for 150kW diesel generators, allowing users to choose the most suitable configuration for their specific application and environment. These enclosures can range from basic weatherproof housings to fully sound-attenuated and insulated enclosures, ensuring noise reduction and protection against harsh environmental conditions.

Additionally, some enclosures are designed to meet specific industry standards or certifications, such as hazardous area classifications or outdoor rating requirements, making them suitable for use in specialized applications or regulated environments.

Fuel Tank Configurations

The fuel tank configuration is a critical aspect of a 150kW diesel generator’s design, as it determines the generator’s runtime and autonomy. Manufacturers offer various fuel tank options, including integrated sub-base tanks, external fuel tanks, and custom-sized tanks to meet specific runtime requirements.

Some generators even feature dual-tank configurations or the ability to connect to remote fuel sources, providing extended runtime capabilities and minimizing the need for frequent refueling.

Paralleling and Load Management

In applications where a single 150kW generator may not provide sufficient power or redundancy, manufacturers offer paralleling solutions that allow multiple generators to be interconnected and synchronized. This feature enables load sharing, increased power output, and improved reliability through redundancy.

Advanced load management systems can also be integrated, automatically distributing the load across multiple generators for optimal efficiency and load balancing.

Remote Monitoring and Control

Modern 150kW diesel generators often incorporate advanced remote monitoring and control capabilities, allowing users to monitor and manage the generator’s performance from a central location or even remotely via web-based interfaces or mobile applications.

These systems provide real-time data on parameters such as fuel levels, runtime, load levels, and fault diagnostics, enabling proactive maintenance and minimizing downtime. Some systems even allow for remote start/stop control, further enhancing operational efficiency and convenience.

Auxiliary Equipment Integration

Depending on the application, 150kW diesel generators may require integration with auxiliary equipment or systems. Manufacturers offer a range of compatible accessories and integration options, such as automatic transfer switches (ATS), load banks, battery chargers, and exhaust systems.

These integration options ensure seamless operation and compatibility with existing infrastructure, while also providing additional features and functionality to meet specific operational requirements.

Section 9: Installation and Siting Considerations

Proper installation and siting are crucial factors in ensuring the optimal performance, safety, and longevity of a 150kW diesel generator. Manufacturers and industry experts provide comprehensive guidelines and best practices to help users navigate the installation process and address various considerations.

Site Selection and Preparation

Selecting the right site for a 150kW diesel generator installation is essential. Factors such as accessibility, clearance requirements, ventilation, and proximity to critical loads must be carefully evaluated. Site preparation may involve tasks like leveling, constructing concrete pads or foundations, and ensuring adequate drainage and spill containment measures.

Fuel Storage and Supply

Proper fuel storage and supply are critical for the reliable operation of a 150kW diesel generator. Considerations include the size and location of fuel tanks, fuel delivery logistics, and compliance with local regulations and safety standards. Manufacturers often provide guidance on fuel tank sizing and placement to ensure sufficient runtime and minimize the risk of fuel-related issues.

Exhaust and Ventilation Systems

Exhaust and ventilation systems are vital components of a 150kW diesel generator installation. Proper exhaust routing and ventilation ensure the safe removal of combustion gases and prevent the buildup of harmful emissions. Compliance with local building codes and environmental regulations is essential when designing and installing these systems.

Noise Mitigation and Vibration Control

Noise and vibration are common concerns when Directly continue the article from where it left off.

Noise and vibration are common concerns when installing a 150kW diesel generator. Manufacturers offer various solutions, such as sound-attenuated enclosures, vibration isolation mounts, and exhaust silencers, to mitigate these issues and ensure compliance with local noise regulations and occupational safety standards.

Electrical Integration and Load Connections

Proper electrical integration is crucial for the safe and efficient operation of a 150kW diesel generator. This includes sizing and installing appropriate cables, switchgear, and distribution panels to handle the generator’s output. Load connections must be carefully planned and executed to ensure proper load distribution and avoid overloading the generator.

In many cases, an automatic transfer switch (ATS) is installed to seamlessly transition between utility power and generator power during outages or maintenance periods. Proper load bank testing and commissioning are also recommended to verify the generator’s performance and ensure it meets the specified load requirements.

Compliance with Codes and Regulations

Installing a 150kW diesel generator requires adherence to various local, state, and federal codes and regulations. These may include building codes, electrical codes, environmental regulations, and zoning ordinances. Working with experienced professionals and obtaining the necessary permits and approvals is essential to ensure compliance and avoid potential fines or legal issues.

Maintenance and Service Considerations

Proper maintenance and service are crucial for ensuring the longevity and reliable operation of a 150kW diesel generator. Manufacturers provide detailed maintenance schedules and recommendations, including regular inspections, oil and filter changes, coolant replacements, and other preventive maintenance tasks.

Additionally, it is essential to have a service plan in place, either through the manufacturer’s authorized service providers or qualified third-party contractors. Regular load bank testing, fuel system maintenance, and generator exercising are also recommended to ensure the generator is ready to perform when needed.

Section 10: Backup Power Solutions for Critical Infrastructure

In today’s interconnected world, the reliable operation of critical infrastructure is essential for maintaining public safety, economic stability, and societal well-being. The 150kW diesel generator plays a vital role in providing backup power solutions for these critical systems, ensuring continuity of operations during power outages or emergencies.

Data Centers and Communication Networks

Modern data centers and communication networks are the backbone of the digital age, enabling the seamless flow of information and data that drives businesses, governments, and societies. A power outage in these facilities can result in catastrophic data loss, disruption of services, and significant financial consequences.

The 150kW diesel generator serves as a robust and reliable backup power source for data centers and communication networks, ensuring uninterrupted operation and minimizing the risk of costly downtime. These generators are designed to seamlessly take over the power load within seconds of an outage, providing a seamless transition and preventing data loss or service disruptions.

Healthcare Facilities and Emergency Services

In the healthcare sector, reliable power is not just a matter of convenience; it is a matter of life and death. Hospitals, clinics, and emergency response centers rely on a constant supply of electricity to power life-support equipment, diagnostic tools, and critical communication systems.

The 150kW diesel generator plays a crucial role in ensuring the continuity of these vital services during power outages or emergencies. By providing backup power, these generators help healthcare facilities maintain essential operations, ensure patient safety, and support emergency response efforts, ultimately saving lives and minimizing the impact of critical situations.

Transportation and Traffic Control Systems

Modern transportation systems, including airports, railways, and traffic control networks, depend heavily on reliable power sources to ensure safe and efficient operations. A power outage in these systems can lead to significant disruptions, delays, and potential safety hazards.

The 150kW diesel generator serves as a critical backup power solution for transportation and traffic control systems, ensuring that essential systems such as signaling, lighting, and communication networks remain operational during power outages. This not only minimizes disruptions and delays but also helps maintain public safety and prevent potential accidents or incidents.

Water and Wastewater Treatment Facilities

Water and wastewater treatment facilities play a vital role in maintaining public health and environmental sustainability. These facilities require a constant supply of electricity to operate pumps, filtration systems, and other critical equipment necessary for treating and distributing clean water, as well as processing and treating wastewater.

The 150kW diesel generator provides a reliable backup power solution for these facilities, ensuring that essential operations can continue uninterrupted during power outages. This not only helps maintain the supply of clean water but also prevents the potential release of untreated wastewater, which could have severe environmental and public health consequences.

Industrial and Manufacturing Facilities

In the industrial and manufacturing sectors, power outages can result in significant production losses, equipment damage, and financial implications. Many industrial processes and automated systems rely on a continuous supply of electricity to operate safely and efficiently.

The 150kW diesel generator serves as a dependable backup power source for these facilities, minimizing the impact of power outages and ensuring that critical processes can continue without interruption. This not only helps maintain productivity and minimize financial losses but also ensures the safety of workers and prevents potential hazards associated with interrupted industrial processes.

By providing backup power solutions for these critical infrastructure systems, the 150kW diesel generator plays a vital role in maintaining public safety, economic stability, and the continuity of essential services that support modern societies.

Section 11: Rental and Temporary Power Solutions

While many businesses and organizations invest in owning their own 150kW diesel generators, there are situations where renting or utilizing temporary power solutions may be more practical or cost-effective. The versatility of these generators makes them well-suited for a wide range of temporary power applications.

Construction and Event Power

Construction sites and outdoor events often require reliable and portable power sources to support various activities and equipment. The 150kW diesel generator serves as an ideal solution for these applications, providing ample power to run tools, lighting, temporary structures, and other essential equipment.

Many rental companies offer 150kW diesel generators mounted on trailers or skids, making them easy to transport and set up at remote locations. These generators can be quickly deployed and configured to meet the specific power requirements of construction projects or large-scale events, ensuring uninterrupted operations and minimizing disruptions.

Emergency and Disaster Response

In the aftermath of natural disasters or emergencies, reliable power sources are critical for supporting relief efforts, temporary shelters, and essential services. The 150kW diesel generator plays a vital role in these situations, providing a flexible and rapidly deployable power solution.

Emergency response organizations and government agencies often maintain fleets of 150kW diesel generators that can be quickly mobilized and dispatched to affected areas. These generators can power field hospitals, communication systems, water treatment facilities, and other critical infrastructure, ensuring that essential services remain operational during the recovery and rebuilding phases.

Remote Site Power

Many industries, such as mining, oil and gas exploration, and remote research facilities, operate in areas where grid power is unavailable or unreliable. In these situations, the 150kW diesel generator serves as a reliable and self-contained power source, enabling continuous operations and supporting critical equipment and infrastructure.

Rental companies offer specialized 150kW diesel generators designed for remote site applications, featuring rugged construction, extended runtime capabilities, and easy transportability. These generators can be delivered and set up on-site, providing a turnkey power solution that minimizes downtime and ensures uninterrupted operations in even the most challenging environments.

Temporary Power During Maintenance or Upgrades

Businesses and organizations often require temporary power solutions during planned maintenance or upgrade activities on their primary power systems. The 150kW diesel generator provides a convenient and reliable solution for these situations, ensuring that critical operations can continue without interruption.

Rental companies can provide 150kW diesel generators on a temporary basis, allowing businesses to seamlessly transition their power load to the rental units during maintenance or upgrade periods. This minimizes downtime, ensures business continuity, and provides a cost-effective alternative to shutting down operations or investing in permanent backup power systems.

By offering flexible rental and temporary power solutions, the 150kW diesel generator industry enables businesses, organizations, and government agencies to access reliable and portable power sources when and where they are needed most.

Section 12: Maintenance and Service Considerations

Proper maintenance and service are crucial for ensuring the reliable and efficient operation of a 150kW diesel generator throughout its lifespan. Neglecting maintenance can lead to decreased performance, increased operating costs, and potential breakdowns, which can result in costly downtime and disruptions.

Manufacturer Recommendations

Manufacturers of 150kW diesel generators provide comprehensive maintenance schedules and guidelines tailored to their specific models. These recommendations cover various aspects of maintenance, including routine inspections, fluid changes, filter replacements, and component replacements at specified intervals.

Adhering to these manufacturer recommendations is essential to ensure the generator operates within its designed parameters and maintains its performance, efficiency, and emissions compliance. Deviating from these guidelines can void warranties and potentially lead to premature component failures or other issues.

Preventive Maintenance Programs

Implementing a structured preventive maintenance program is highly recommended for 150kW diesel generators. These programs involve scheduling regular maintenance tasks, such as oil and filter changes, coolant replacements, battery inspections, and belt adjustments, at predetermined intervals based on operating hours, runtime, or calendar schedules.

Preventive maintenance programs not only help maintain the generator’s performance but also enable early detection and resolution of potential issues before they escalate into more significant problems. This proactive approach can extend the generator’s lifespan, reduce unplanned downtime, and ultimately lower overall maintenance costs.

Trained Technicians and Service Providers

Proper maintenance and service of 150kW diesel generators should be performed by trained and qualified technicians. Manufacturers often have authorized service providers or dealer networks that employ factory-trained technicians with the necessary expertise and access to genuine parts and specialized tools.

Working with these authorized service providers can ensure that maintenance and repairs are carried out correctly, using the proper procedures and genuine replacement parts. This not only helps maintain the generator’s performance and reliability but also preserves any applicable warranties and ensures compliance with emissions regulations.

Load Bank Testing and Commissioning

Load bank testing is an essential aspect of maintaining and verifying the performance of a 150kW diesel generator. This process involves connecting the generator to a specialized load bank that simulates various load conditions, allowing technicians to assess the generator’s output, efficiency, and overall performance under different scenarios.

Load bank testing is typically performed during commissioning, after major repairs or overhauls, and as part of routine maintenance programs. This testing helps identify potential issues, verify the generator’s ability to handle its rated load, and ensure it meets the specified performance requirements.

Fuel System Maintenance

The fuel system is a critical component of a 150kW diesel generator, and proper maintenance is essential to ensure reliable operation and prevent fuel-related issues. This includes regular inspections and cleaning of fuel tanks, filters, and lines to remove any contaminants or water accumulation.

Additionally, fuel quality should be monitored, and appropriate fuel treatments or additives may be necessary to maintain fuel stability and prevent degradation over time. Following manufacturer recommendations for fuel system maintenance can help prevent issues such as clogged filters, fuel pump failures, and injector problems, which can lead to decreased performance or generator downtime.

By implementing a comprehensive maintenance and service program, businesses and organizations can maximize the lifespan, reliability, and efficiency of their 150kW diesel generators, ensuring they are prepared to provide backup power when needed most.