Table of Contents

Toggle

In an era where the reliance on power for both daily operations and emergency situations is paramount, the diesel generator stands as a cornerstone of backup and primary power solutions across various industries. Demanded not just for its reliability, but also for its efficiency and longevity, understanding the basics of how a diesel generator functions and its pivotal role in today’s energy-reliant society is essential. This piece aims to shed light on this critical equipment, offering insights into its operation, benefits, and practical applications, making it invaluable for anyone looking to bolster their power generation capabilities or simply aiming to augment their knowledge about one of the most dependable sources of alternative power.

This article delves deep into the realm of diesel generators, covering a broad spectrum of relevant topics. Readers will gain an understanding of what a diesel generator is, the principles behind its operation, and the myriad uses it boasts in both commercial and residential sectors. Furthermore, the discussion will navigate through the advantages of choosing a diesel generator, the different types available in the market, the essential components constituting a diesel generator, and key considerations for selecting the right fit for specific needs. To ensure longevity and optimal performance, maintenance tips for diesel generators will also be explored, rounding off a comprehensive guide designed to equip readers with the knowledge to make informed decisions regarding diesel generators.

What is a Diesel Generator?

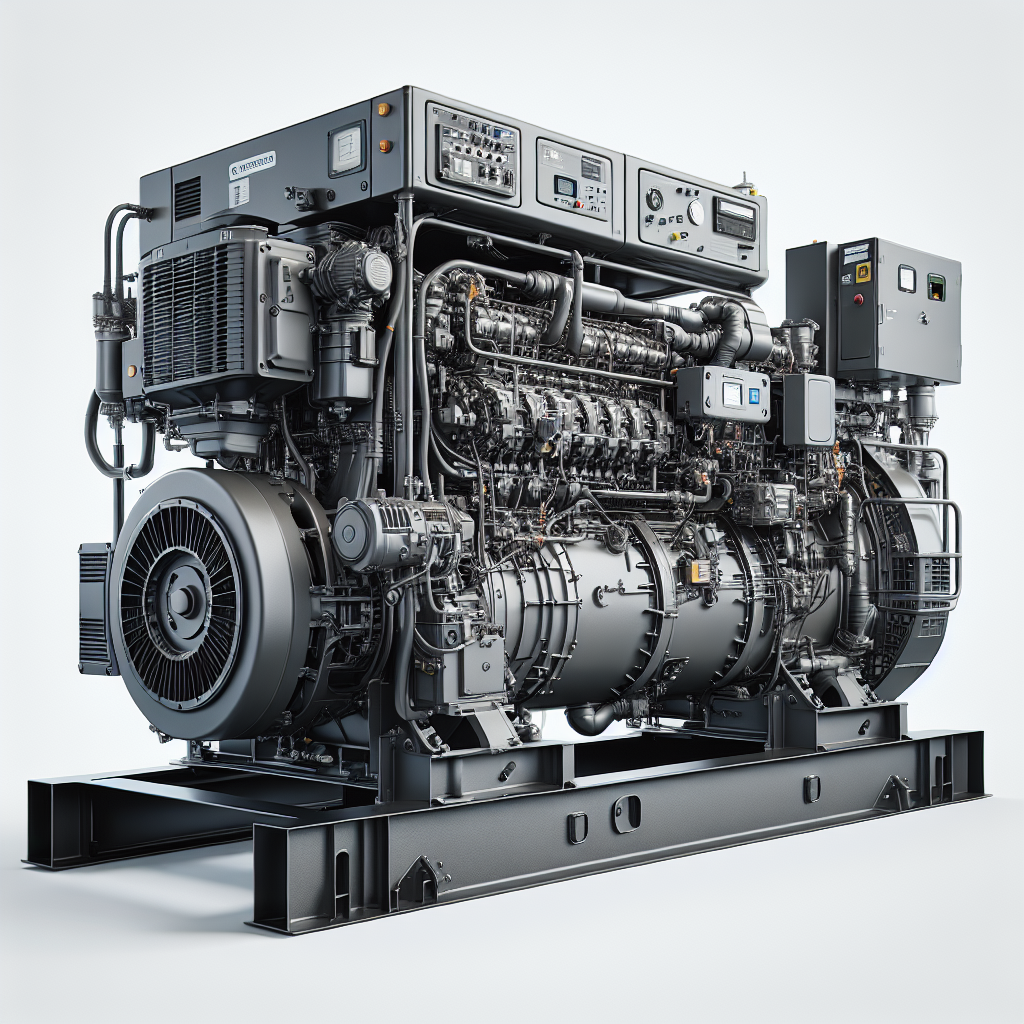

A diesel generator, often referred to as a diesel genset, is an integrated system that combines a diesel engine with an electric generator, typically an alternator, to produce electrical energy. This setup is a specialized form of engine generator. Primarily, diesel generators function on diesel fuel, although some models are adapted to utilize other liquid fuels or natural gas.

The core utility of diesel generators lies in their ability to provide power in areas that lack connections to a power grid, or serve as an emergency power supply during grid failures. Beyond these basic applications, diesel generators are also employed for more complex tasks such as peak-lopping, grid support, and even exporting power back to the grid during times of power surplus.

The assembly of a diesel generator includes not just the engine and generator, but also an array of auxiliary devices. These devices encompass the base, canopy for noise reduction, control systems, circuit breakers, jacket water heaters, and the starting system, collectively known as a “generating set” or “genset.”

One of the standout features of diesel generators is their dual functionality. While primarily known for emergency power provision, they can also contribute power to utility grids during peak periods or when there is a shortfall in large power generators. This dual capability makes them a versatile choice for various settings, from residential to industrial applications.

Moreover, the operation of a diesel generator begins with the combustion of diesel fuel in the engine. This process involves the mixing of air with injected fuel, which ignites due to high compression, generating heat. This heat then converts chemical energy into mechanical energy through the movement of pistons. These pistons drive a crankshaft which, in turn, powers the alternator. The alternator then produces electrical energy through electromagnetic induction, ensuring a steady supply of power.

Diesel generators are recognized for their consistent power output and efficiency, thanks to the inherent qualities of the diesel engine, which includes a high thermal efficiency and the ability to operate on various fuel types. This versatility, coupled with their robust construction, makes diesel generators a reliable source of power in diverse and demanding environments.

How Diesel Generators Work

Combustion Process

Diesel generators operate by converting the chemical energy of diesel fuel into mechanical energy through combustion. The process starts with diesel fuel being injected into the engine’s combustion chamber. Here, the fuel is atomized into tiny droplets and sprayed into highly compressed air within the engine cylinder. Due to the high compression ratios in diesel engines, the temperature and pressure of the air are significantly increased, leading to the auto-ignition of the diesel fuel without the need for an external ignition source like spark plugs.

The combustion of the fuel-air mixture creates a high-pressure gas, which drives the piston downward during the expansion stroke. This motion converts the chemical energy from the burning fuel into mechanical energy.

Conversion to Electrical Energy

The mechanical energy generated by the movement of the piston is transmitted through the engine’s crankshaft. This crankshaft is connected to a rotor in the generator’s alternator. As the rotor spins within a magnetic field, it induces an electrical current in the alternator’s windings. The rotation of the rotor and the interaction with the magnetic field are crucial for generating electricity.

Diesel generators typically produce alternating current (AC) electricity, with the frequency and voltage levels determined by the design and speed of the generator. A voltage regulation system is included to ensure a consistent output voltage, adjusting the field current in the alternator to maintain the desired voltage level despite load variations.

These generators are equipped with various controls that allow users to start, stop, and control the power output, catering to changes in power demand. Additionally, to manage the significant heat generated during operation, diesel engines are equipped with cooling systems that use coolant to dissipate the heat. Lubrication systems are also essential to ensure that moving parts within the engine are properly oiled to reduce friction and wear.

Common Uses of Diesel Generators

Residential

Diesel generators are a reliable source of backup power for residential use, especially during unexpected power outages. These generators, which feature internal combustion engines that run on diesel fuel, are both economical and safe. Diesel fuel has a long shelf life and is less flammable compared to other fuel types, making it a safer choice for home use. Residential diesel generators are available in portable forms for temporary use or as permanent home standby generators, ensuring that households remain powered during emergencies, thus keeping families safe and protected.

Commercial

In the commercial realm, diesel generators are indispensable for maintaining continuous operations during power outages. They are commonly used in businesses, office buildings, and various commercial facilities to ensure that critical operations do not suffer interruptions. The versatility of diesel generators means they are also employed across diverse industries for backup and even as primary power sources during bad weather or other disruptions. Their ability to support essential services like lighting, heating, cooling, and critical systems makes them a staple in commercial settings.

Industrial

Industrial diesel generators play a crucial role in powering large-scale operations such as manufacturing plants, construction sites, and warehouses. These generators are designed for heavy-duty use and continuous operation, providing the necessary power to keep industrial processes running smoothly even during grid failures. The robust construction of industrial diesel generators allows them to handle the demanding environments of industrial applications, ensuring that operations are not halted by power disruptions. They are particularly vital in areas not served by the main power grid or in situations where grid power is unreliable.

Advantages of Diesel Generators

Reliability

Diesel generators are highly regarded for their reliability, especially in providing emergency power. With the ability to run at a minimum of 12,000 hours and up to 20,000 hours before requiring significant maintenance, they ensure continuous operation critical for businesses. The inherent design of diesel generators allows them to operate efficiently under a variety of environmental conditions, further enhancing their reliability.

Durability

The robust construction of diesel generators contributes to their extended lifespan and durability. Designed to withstand rigorous use, they are ideal for harsh industrial environments. Diesel engines, made with fewer moving and more durable parts, experience less wear over time compared to their gasoline counterparts. This structural integrity means diesel generators can handle larger power loads and continue operating effectively for many years, making them a cost-effective solution for long-term energy needs.

Efficiency

Diesel generators excel in efficiency due to their unique combustion process, where air and fuel are introduced and compressed separately, allowing them to use less fuel while maintaining high power output. They typically operate at about 40 percent efficiency, significantly higher than other generator types. This efficiency is further underpinned by diesel’s higher energy density compared to natural gas, providing more energy per unit and making diesel generators a preferred choice for effective power generation. Additionally, modern diesel generators equipped with advanced technologies like the Volvo Penta D13 engine optimize fuel usage and reduce emissions, enhancing overall efficiency and reducing operational costs.

Types of Diesel Generators

Diesel generators are essential for various applications and are categorized based on their operational modes, which include Standby Power, Prime Power, and Continuous Power. Each type serves a specific function, tailored to meet different power needs and scenarios.

Standby Power

Standby generators are crucial for emergency use, designed to operate only during power outages. They provide a temporary power solution, ensuring that essential systems remain operational until the main power supply is restored. These generators are characterized by their ability to handle short-duration operations, making them ideal for residential and small business applications where power interruptions are infrequent but critical. Standby generators typically feature simpler cooling systems due to their intermittent use, which does not generate excessive heat, thereby reducing the complexity and cost of the unit.

Prime Power

Prime generators are intended for long-term use as the main power source, especially in remote locations without grid access, such as mining sites or large-scale construction projects. Unlike standby generators, prime generators can handle variable loads over extended periods. They are built to endure the rigors of continuous operation, with robust components that can withstand significant wear and tear. This capability makes them more expensive but highly reliable for critical operations where consistent power is necessary.

Continuous Power

Continuous generators are the powerhouse among generator types, designed to operate non-stop as a primary power source with a constant load. These are typically used in critical applications such as hospitals, data centers, and industrial facilities where power is crucial for ongoing operations. Continuous generators are engineered to perform under demanding conditions for prolonged periods without interruption, making them indispensable in settings that require a high degree of reliability and performance.

Each type of diesel generator offers distinct advantages and is suited for specific scenarios, from emergency backup to continuous power provision. Understanding these types can help users select the most appropriate generator for their needs, ensuring efficient and reliable power supply in various operational environments.

Components of a Diesel Generator

Diesel Engine

The diesel engine is the primary source of mechanical energy in a diesel generator. It converts the chemical energy stored in diesel fuel into mechanical energy through the combustion process. The size and power output of the engine are crucial as they determine the generator’s overall capacity. Larger engines enable the production of more power, making them essential for high-demand applications.

Alternator

Connected directly to the diesel engine, the alternator plays a critical role in converting mechanical energy into electrical energy. It consists of a rotor and a stator; the rotor spins driven by the engine, creating a magnetic field around the stationary stator, which in turn induces electrical current. This process is fundamental to generating the alternating current (AC) electricity that diesel generators provide.

Fuel System

The fuel system is integral to the operation of a diesel generator. It includes a fuel tank, fuel filters, and fuel injectors that supply diesel to the engine. The size of the fuel tank affects how long the generator can operate before needing a refill. Properly designed fuel systems ensure efficient fuel delivery to the engine, supporting continuous and reliable generator operation.

Voltage Regulator

This component is crucial for maintaining a stable voltage output from the generator. The voltage regulator adjusts the field current supplied to the alternator, ensuring that the generator produces a consistent voltage level regardless of load changes. This stability is vital for protecting connected electrical devices from voltage fluctuations.

Cooling & Exhaust System

To prevent overheating, diesel generators are equipped with a cooling system that typically includes a radiator and a cooling fan. These components work together to dissipate excess heat generated by the engine during operation. Additionally, the exhaust system channels the combustion gases away from the engine, helping maintain optimal operating temperatures and reducing the risk of overheating.

Control Panel

The control panel is the user interface of the diesel generator, housing essential controls and monitoring instruments. It typically features start/stop buttons, voltage and frequency gauges, circuit breakers, and alarms for fault detection. This panel allows operators to manage the generator’s performance and ensures smooth operation by providing real-time data and controls.

Selecting the Right Diesel Generator

Selecting the right diesel generator involves understanding specific requirements and conditions to ensure optimal performance and efficiency. Below are crucial factors to consider:

Power Requirements

The first step in selecting a diesel generator is determining the power needs of your operation. Start by listing all critical equipment and systems that require power during an outage. This list should include not only essential machinery but also support systems like lighting and computers. Calculate both the starting wattage, which is higher due to initial energy demand, and the running wattage. It’s advisable to select a generator with a capacity 5%-10% higher than your maximum calculated requirement to handle unexpected increases in load and to ensure reliability.

Fuel Consumption

Fuel efficiency is a significant factor when choosing a diesel generator. Generators are rated in kilo-volt-amperes (kVA), but actual power output is measured in kilowatts (kW). Since not all the power used by a generator produces useful work output due to system inefficiencies, it’s essential to understand the relationship between kVA and kW and choose a generator with an appropriate power factor, generally around 0.8. Consider the fuel consumption rates at different loads, as efficiency varies significantly under partial load conditions. Selecting a generator that operates efficiently at your typical load level can result in substantial fuel savings and reduced operating costs.

Environment Considerations

The environmental impact of operating a diesel generator is another critical consideration. Diesel engines emit nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO), which can affect air quality and health. Newer models that comply with recent emission standards and use ultra-low sulfur diesel (ULSD) or biodiesel can significantly reduce these emissions. Additionally, features like diesel particulate filters and selective catalytic reduction systems can further mitigate environmental impact. When choosing a generator, consider the balance between power needs, fuel efficiency, and environmental sustainability to ensure compliance with regulations and corporate social responsibility goals.

By carefully evaluating these aspects, businesses and organizations can select a diesel generator that meets their power requirements while optimizing fuel consumption and minimizing environmental impact.

Maintenance Tips for Diesel Generators

Regular Servicing

Maintaining a diesel generator involves regular inspections and servicing to ensure optimal performance and prevent unexpected failures. Key components such as the fuel system, cooling system, and electrical connections should be checked thoroughly. Regular servicing schedules are crucial, as they help identify potential issues early, preventing them from escalating into major problems. It’s recommended to schedule preventative maintenance checks regularly, which include visual and operational inspections by trained personnel.

Oil and Filter Changes

The lifeblood of any diesel generator is its oil, which lubricates and protects the engine’s moving parts. Regular oil and filter changes are essential to maintain the generator’s efficiency and longevity. It is recommended to change the oil and filter every 500 hours of operation, but this can vary based on the generator’s usage and operational conditions. Always consult the engine manufacturer’s guidelines for specific maintenance schedules and procedures to ensure proper handling and disposal of used oil and filters.

Coolant System Maintenance

The coolant system plays a critical role in regulating the engine’s temperature and preventing overheating. Check the coolant level regularly, especially during shutdown periods. If the coolant level is low, refill it to approximately 3/4 inch to maintain the correct balance of water, antifreeze, and coolant additives. It’s also important to inspect the radiator for any blockages and clean the exterior using a soft brush or low-pressure compressed air to remove dirt and debris, ensuring efficient operation.

Conclusion

Throughout this article, we’ve explored the fundamental aspects of diesel generators, covering their operation, benefits, applications, and maintenance practices. From understanding how these robust machines convert diesel fuel into electrical power to recognizing their indispensable role in residential, commercial, and industrial settings, it’s clear that diesel generators are pivotal in ensuring continuity of operations and safety in power-deficient situations. The discussion underscored not just their utility in emergency and off-grid scenarios but also highlighted the considerations necessary for selecting the right generator, emphasizing on power requirements, environmental factors, and efficiency.

As we conclude, it’s evident that the informed selection and maintenance of a diesel generator can significantly enhance its performance and lifespan, contributing to both operational reliability and sustainability. Whether for emergency backup, continuous power supply, or supporting critical systems during power outages, diesel generators present a reliable solution, backed by the capability to meet diverse power needs effectively. Reflecting on their advantages and the strategic insight provided on maintenance, the guide underscores the importance of diesel generators in today’s energy-reliant society, offering a comprehensive resource for anyone looking to make informed decisions in this vital area.