Table of Contents

ToggleIntroduction

Imagine a world where power outages are as frequent as daily meals. Sounds inconvenient, right? This is where industrial diesel generators step in as unsung heroes, tirelessly working behind the scenes to ensure that critical operations continue seamlessly. From bustling urban centers to remote rural outposts, these machines are the silent guardians of electricity. But what makes them so indispensable? Let’s embark on a journey to explore the fascinating world of industrial diesel generators.

What is an Industrial Diesel Generator?

Definition and Basic Components

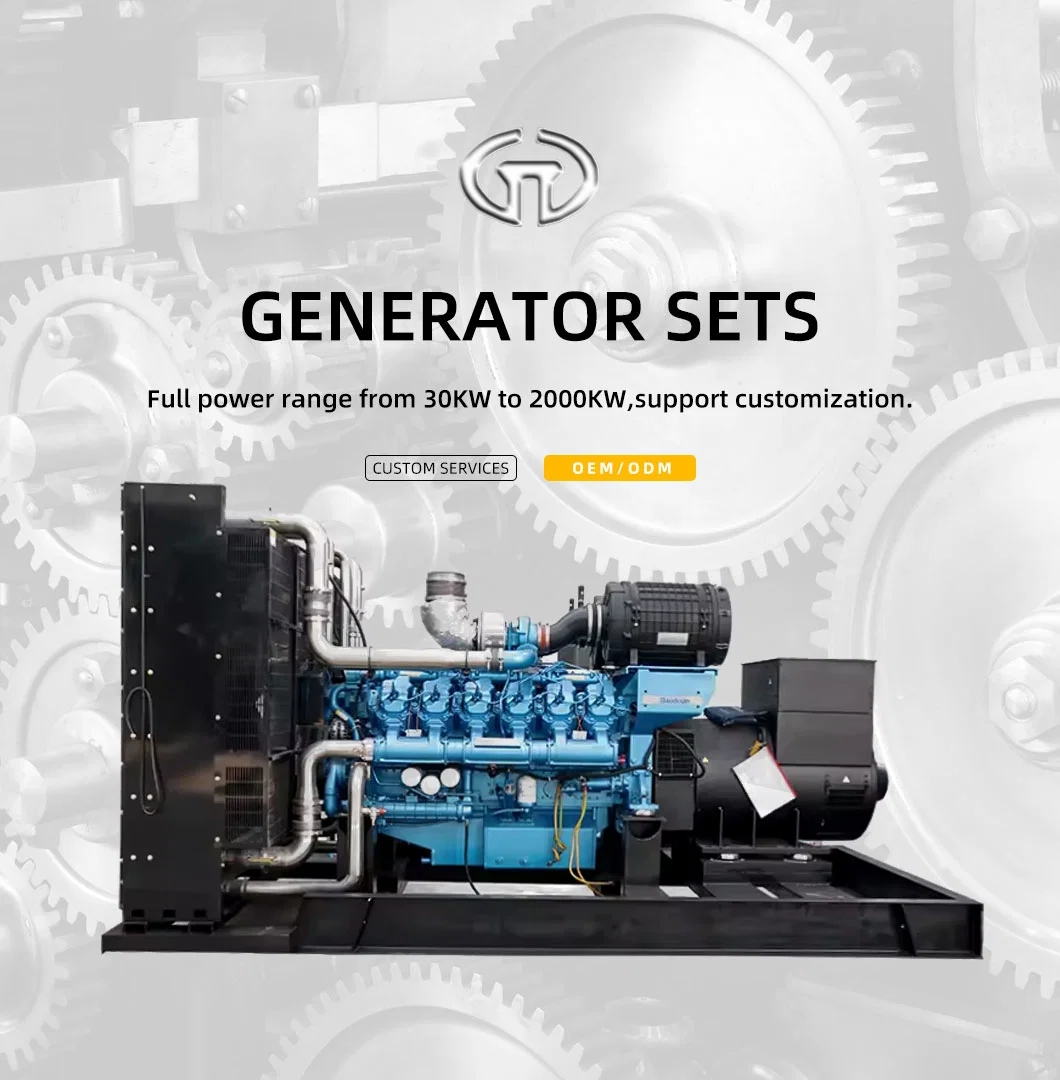

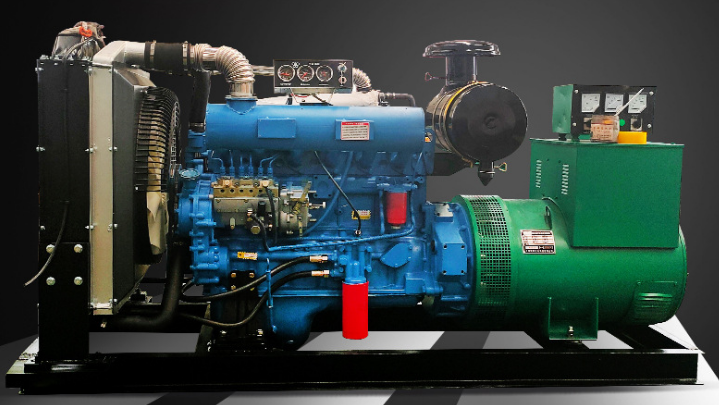

At its essence, an industrial diesel generator is a robust machine designed to convert mechanical energy into electrical energy. It comprises several key components: the diesel engine, the alternator, the fuel system, the control panel, and the cooling and exhaust systems. Each part plays a crucial role in ensuring the generator functions effectively and efficiently.

- Diesel Engine: This is the heart of the generator. It burns diesel fuel to produce mechanical energy. Known for their durability and reliability, diesel engines are built to withstand long hours of operation.

- Alternator: The alternator converts mechanical energy from the engine into electrical energy. It comprises a rotor and a stator that work together to produce alternating current (AC) power.

- Fuel System: This includes the fuel tank, fuel pump, and fuel lines. It ensures a steady supply of diesel to the engine.

- Control Panel: This is the brain of the generator. It allows operators to monitor and control various parameters such as voltage output, frequency, and engine speed.

- Cooling and Exhaust Systems: These systems prevent overheating and manage exhaust emissions, ensuring safe and efficient operation.

How It Works

The operation of an industrial diesel generator can be likened to a well-choreographed dance. The process begins with the diesel engine igniting fuel in its cylinders, creating an explosion that pushes pistons. These pistons then turn the crankshaft, generating mechanical energy. This energy spins the alternator’s rotor within a magnetic field, producing electricity through electromagnetic induction. The result? A reliable stream of power ready to be distributed wherever it’s needed.

Types of Industrial Diesel Generators

Standby Generators

Standby generators are like your emergency backup plan—they spring into action during unexpected power outages. Typically installed in permanent locations, these generators automatically detect when the main power supply fails and kick in within seconds. They are ideal for facilities that cannot afford downtime, such as hospitals and data centers.

Prime Power Generators

Unlike standby generators, prime power generators are designed for continuous operation. They are perfect for sites where grid power is unavailable or unreliable, such as remote mining operations or off-grid construction projects. These generators provide consistent power over extended periods, ensuring smooth operations in challenging environments.

Portable Generators

Portable generators are the Swiss Army knives of the generator world. Compact yet powerful, they are designed for mobility and versatility. Whether you’re hosting an outdoor event or working on a temporary project site, portable generators provide flexible power solutions that can be easily transported wherever needed.

Key Features and Specifications

Power Output

One of the first considerations when selecting a diesel generator is its power output, typically measured in kilowatts (kW) or megawatts (MW). The required power output depends on the intended application—whether it’s powering a small business or supporting large-scale industrial operations.

Fuel Efficiency

Fuel efficiency is a critical factor that influences operational costs. Diesel generators are known for their superior fuel efficiency compared to gasoline generators. They provide more energy per gallon of fuel, making them cost-effective options for long-term use.

Noise Levels

Operating noise can be a concern, especially in residential areas or quiet work environments. Many modern diesel generators are equipped with soundproof enclosures or mufflers to minimize noise levels. When selecting a generator, it’s essential to consider its decibel rating to ensure it meets your specific noise requirements.

Durability and Maintenance

Industrial diesel generators are built to withstand tough conditions, but regular maintenance is vital to ensure their longevity. Features such as sturdy construction materials and easy access to service points can simplify maintenance tasks and extend the generator’s lifespan.

Advantages of Using Diesel Generators

Reliability and Longevity

Diesel generators are celebrated for their reliability and longevity. They can operate for extended periods without overheating or breaking down, making them ideal for critical applications where downtime is not an option. Their robust design ensures they remain operational even in harsh environments.

Cost-Effectiveness

While the initial investment for a diesel generator may be higher than other types, their lower operational costs make them more economical in the long run. Diesel fuel is generally cheaper than other fuels, and their superior efficiency means less fuel consumption over time.

Performance Under Harsh Conditions

Diesel generators are engineered to perform in challenging conditions where other power solutions might fail. Whether it’s extreme temperatures or remote locations with limited access to resources, these generators deliver reliable power without compromise.

Applications of Industrial Diesel Generators

Construction Industry

In the construction industry, where the work never stops, industrial diesel generators are indispensable. They provide the necessary power to operate heavy machinery and tools on job sites that often lack reliable grid connections. Whether it’s a towering crane or a jackhammer, these generators ensure that construction projects proceed smoothly, regardless of location or time constraints. Imagine a construction site as a bustling orchestra, with each piece of equipment playing its part—diesel generators are the conductors, keeping everything in harmony.

Healthcare Facilities

For healthcare facilities, uninterrupted power is a matter of life and death. Hospitals and clinics rely on diesel generators to maintain critical systems such as life support machines, medical refrigerators, and lighting during power outages. The reliability of these generators ensures that patient care remains uncompromised even when external power sources fail. It’s like having a guardian angel watching over the facility, ready to step in at a moment’s notice.

Data Centers

In today’s digital age, data centers are the nerve centers of information technology. These facilities demand constant power to keep servers and networking equipment operational around the clock. Diesel generators provide the backup power necessary to prevent data loss and downtime, ensuring that businesses and individuals can access their data without interruption. Think of them as the stalwart sentinels standing guard over vast oceans of data, ensuring they remain safe and accessible.

Agriculture and Rural Areas

In rural areas where access to electricity may be limited, industrial diesel generators offer a lifeline to farmers and agricultural operations. They power irrigation systems, grain silos, and other essential equipment needed for efficient farming practices. By providing reliable electricity, these generators help boost productivity and ensure food security in remote regions. It’s akin to giving farmers the keys to unlock their land’s full potential.

Environmental Considerations

Emissions and Regulations

While diesel generators are incredibly useful, they do come with environmental considerations. Diesel engines emit pollutants such as nitrogen oxides (NOx) and particulate matter (PM), which have raised concerns about air quality and public health. In response, governments worldwide have implemented stricter emissions regulations to curb these impacts. Manufacturers are continually innovating to develop cleaner-burning engines that meet these standards while maintaining performance.

Innovations for Greener Solutions

The push for greener solutions has led to significant advancements in diesel generator technology. Newer models are equipped with features such as advanced exhaust after-treatment systems and hybrid configurations that combine diesel power with renewable energy sources like solar or wind. These innovations not only reduce emissions but also enhance fuel efficiency, offering a more sustainable approach to power generation.

Choosing the Right Diesel Generator

Assessing Power Needs

Selecting the right diesel generator begins with assessing your power needs. Consider the total wattage required by all connected devices and equipment during peak usage. This will help determine the generator’s capacity and ensure it can handle the load without strain.

Considering Space and Installation Requirements

Space constraints and installation requirements play a crucial role in choosing a generator. Evaluate the available space for installation and ensure there’s adequate ventilation to prevent overheating. Some installations may require noise-reducing enclosures or vibration dampening measures to meet specific site conditions.

Evaluating Budget Constraints

Budget is another critical factor when selecting a generator. While it’s tempting to opt for the most powerful model available, it’s essential to balance performance with cost-effectiveness. Consider both upfront costs and long-term operational expenses to make an informed decision that aligns with your financial goals.

Maintenance Tips for Optimal Performance

Regular Inspections and Servicing

To keep your diesel generator running at peak performance, regular inspections and servicing are essential. Routine checks should include inspecting fuel lines for leaks, testing battery voltage, and examining oil levels. Scheduled maintenance ensures any potential issues are identified early before they escalate into costly repairs.

Fuel Management and Storage

Proper fuel management is vital for maintaining generator efficiency. Store diesel fuel in clean, well-ventilated areas away from direct sunlight to prevent contamination or degradation over time. Implementing a fuel rotation schedule can also help ensure that only fresh fuel is used during operation.

Troubleshooting Common Issues

Even with diligent maintenance practices, occasional issues may arise. Common problems include engine starting difficulties, fluctuating power output, or excessive smoke emissions. Familiarize yourself with basic troubleshooting techniques or consult with professionals when necessary to resolve these challenges promptly.

Future Trends in Diesel Generators

Technological Advancements

The future of diesel generators looks promising as technological advancements continue to reshape their capabilities. Innovations such as remote monitoring systems allow operators to track generator performance from anywhere using smartphones or computers—a feature that enhances convenience while optimizing efficiency.

Integration with Renewable Energy Sources

The integration of diesel generators with renewable energy sources is another exciting trend gaining traction globally. Hybrid systems that combine solar panels or wind turbines with traditional diesel power offer a balanced solution that reduces reliance on fossil fuels while maintaining reliable electricity supply—an ideal approach for achieving sustainability goals without compromising reliability.

Conclusion

In conclusion, industrial diesel generators remain indispensable tools across diverse industries due to their unmatched reliability and versatility in delivering uninterrupted power solutions when needed most—whether during emergencies or routine operations alike! As technology continues advancing towards greener alternatives combined seamlessly alongside conventional methods like these trusty machines will undoubtedly play an integral role shaping our energy landscape well into future endeavors too!